Course Materials

GD&T Applications and Tolerance Stacks

2.5-Days (20 Hours)

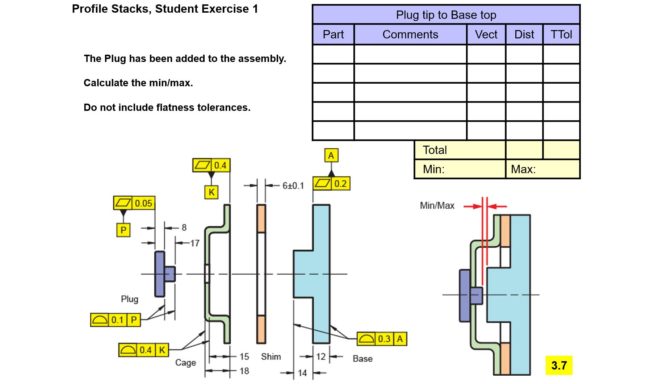

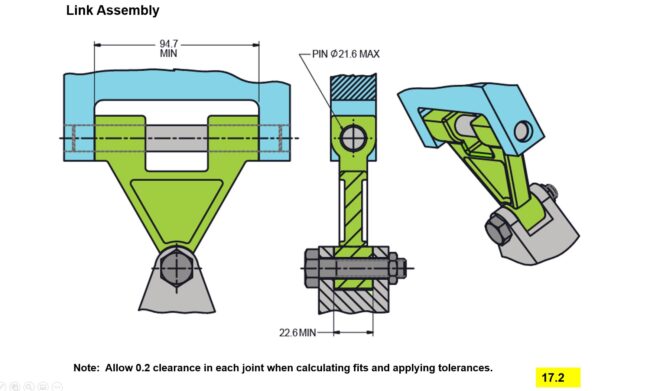

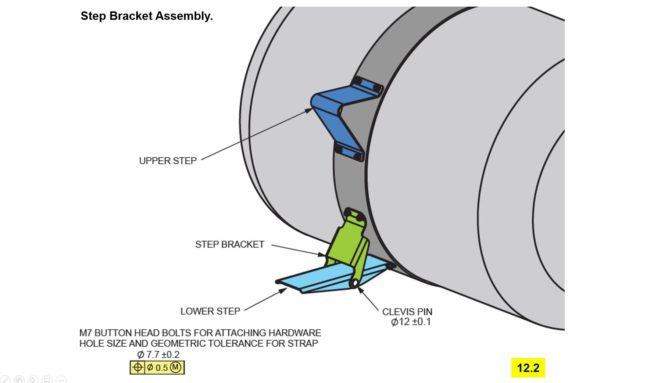

Course Description: This is an advanced level design course for GD&T application and stack up analysis. It includes case-study part drawings as exercises for selecting datum features and applying tolerances. It teaches how to perform tolerance stack loops and analysis across multiple-part assemblies.

Prerequisite: GeoTol Pro GD&T Core Concepts Course

Course Objectives:

- Proper selection of functional datum features

- Apply appropriate tolerance symbols and calculate tolerance values for functional requirements

- Perform tolerance stack loops and transfer data to tables

- Able to reallocate tolerances to meet manufacturing capabilities

- Know differences between worst case analysis and statistical methods (RSS and MRSS)

Targeted Audience: Anyone who needs to author an engineering drawing or do tolerance analysis: personnel in design, or high-level manufacturing and quality

Content Covered: Level 1 core content (16 hours) + select content from Level 2

The combined content from both levels creates the customized course. See below for detailed course content.