Course Materials

GeoTol Pro GD&T Fundamentals Program

Course Objectives

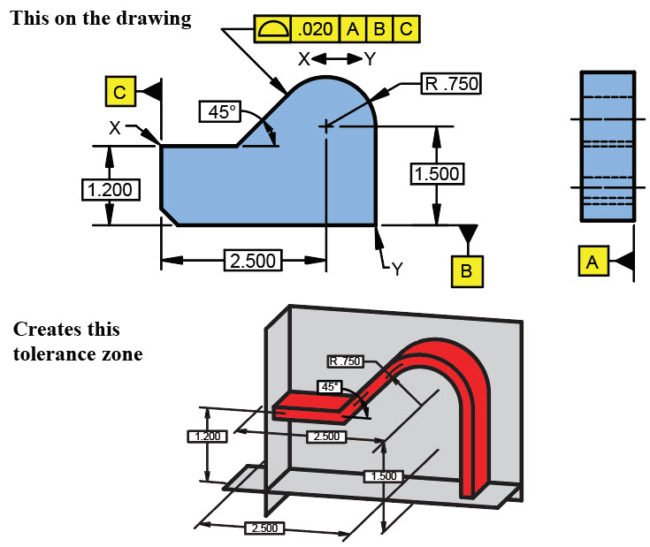

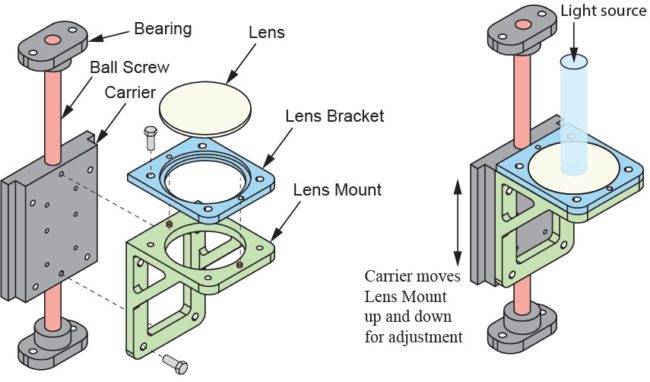

Students will understand the symbols and concepts of geometric dimensioning and tolerancing (GD&T) on engineering drawings. The participants will have knowledge of datum reference frames, form, orientation, profile, position tolerances, modifiers, and common inspection procedures. This GD&T fundamentals course is a great introductory or refresher class.

Targeted Audience: Anyone who needs to read or create an engineering drawing. This course is for mechanical engineers, designers, drafters, quality, inspection, manufacturing, tooling, production, procurement, and purchasing.

Course Highlights

- Course developed and refined for over 40 years

- Great for either an introductory or refresher course

- Adjust your training to GD&T basic, intermediate, or advanced level

- Customizable content for focused training

- Design, quality, and manufacturing personnel in the same class

- Beyond the theory with relatable examples and practical student exercises

- GD&T plastic model parts used for demonstration

- Follows along with the 400-page GeoTol Pro 2020 Workbook

- Updated to the latest ASME Y14.5-2018 (may also include earlier versions)

- May be adjusted to the latest ISO-GPS standards instead