- Orientation Tolerance

Angularity

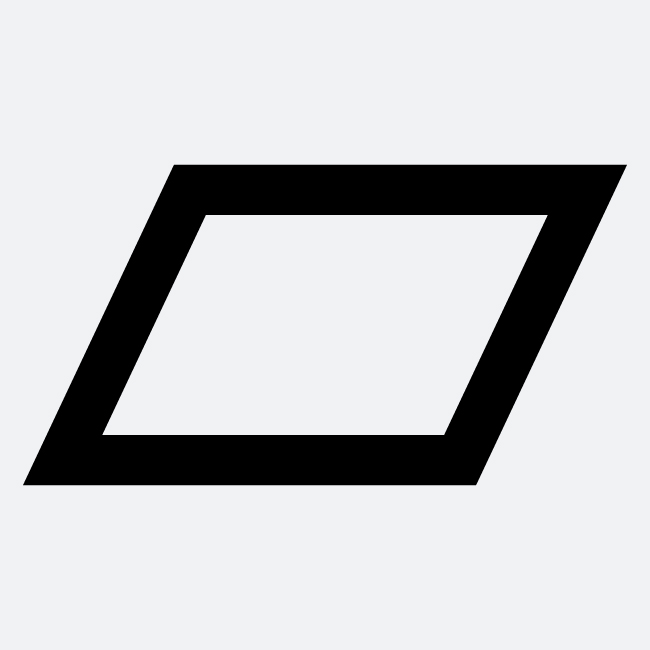

Angularity is a 3D control; the tolerance zone is two parallel planes. Angularity tolerance applied to a plane surface also controls the flatness on the surface.

Click on a GD&T symbol below to find definitions, examples, and concept breakdowns. You can apply a filter by tolerance type to quickly find what you need or browse by alphabetical order. We also include three charts and tables that further explain common drafting symbols encountered on engineering and mechanical drawings.

Angularity is a 3D control; the tolerance zone is two parallel planes. Angularity tolerance applied to a plane surface also controls the flatness on the surface.

Circular runout is a 2D surface to axis control. It creates a series of 2D tolerance zones that apply independently. When applied to a cylindrical feature, each tolerance zone is the radial separation between two circles concentric with the datum…

Circularity is a 2D tolerance. It controls circular elements, not longitudinal elements. Each circular element of the surface in a plane perpendicular to the axis must lie between two concentric circles, one having a radius 0.03 larger than the other.…

Cylindricity is the condition of a surface of revolution within which all points of the surface are equidistant from a common axis.

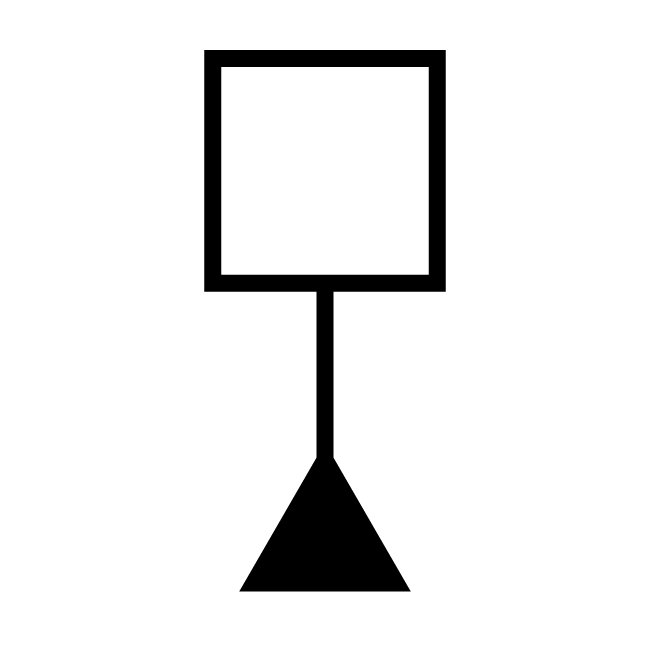

Datum features are the actual, physical features on the part. They are not perfect and will always have manufacturing variation.

The Datum Reference Frame (DRF) consists of 3 planes, 3 axes that are mutually perpendicular and intersect at a point. The DRF is the origin of all the basic dimensions and geometric tolerances. If there is no material condition modifier…

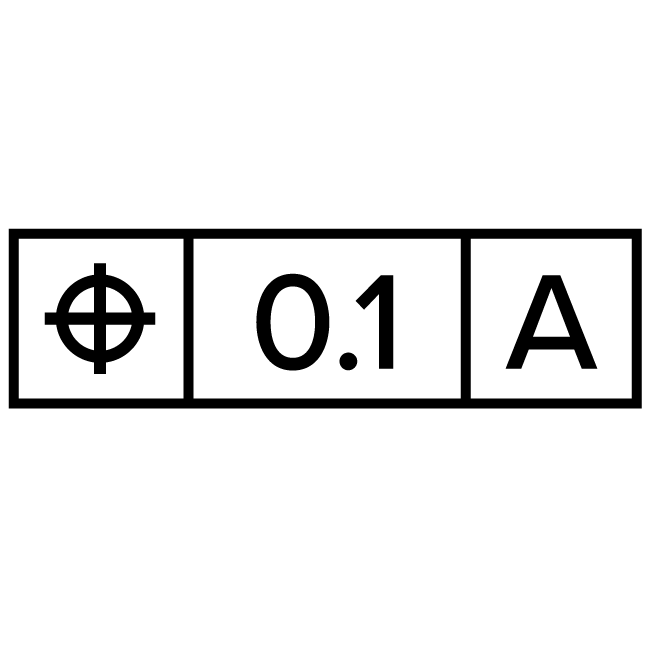

The feature control frame (in ASME) or tolerance indicator (in ISO) is the symbolic means of expressing the tolerance requirements for a feature or set of features.

Flatness is the condition of a surface having all elements in one plane. A flatness tolerance specifies a tolerance zone defined by two parallel planes within which the surface must lie.

The establishment of a Datum Reference Frame (DRF) and geometric tolerances are based on functional design requirements. If there is no material condition modifier following the feature tolerance, the geometric tolerance applies regardless of feature size (RFS). When RFS applies,…

The American Society of Mechanical Engineering (ASME) has published its latest GD&T standard, Y14.5-2018. Here is GeoTol's guide to the most notable changes.

The establishment of a Datum Reference Frame (DRF) and geometric tolerances are based on functional design requirements. If there is no material condition modifier following the feature tolerance, the geometric tolerance applies regardless of feature size (RFS). When RFS applies,…

The least material condition (LMC) of a feature is the biggest hole or smallest pin. An LMC modifier may be applied by placing the circle L symbol in the feature control frame behind the tolerance. This allows additional geometric tolerance…

Features of size (such as holes, slots, tabs and pins) have size tolerance that allow them to be big or small within the tolerance limits. There is often a need to refer to a feature at a specific size limit.…

The maximum material condition (MMC) of a feature is the smallest hole or biggest pin. An MMC modifier may be applied by placing the circle M symbol in the feature control frame behind the tolerance. This allows additional geometric tolerance…

Parallelism is the condition of a surface, axis, or center plane, oriented at 0˚/180˚ to the datum reference frame.

Perpendicularity is the condition of a surface, median plane, or axis oriented at 90˚ to the datum reference frame.

Position tolerance locates features of size. It defines a tolerance zone within which the feature axis or center plane must lie. The size of this zone determines the amount of variation allowed from true (theoretically exact) position. Basic dimensions establish…

Profile of a line specifies a series of 2D cross-sectional tolerance zones along the true profile, within which each 2D surface element must lie. The cross-sections are not compared to each other as a single entity. When used with datum…

By default, profile tolerance specifies a uniform tolerance zone equally distributed about the true profile defined by the basic dimensions. All elements of the surface must lie within the tolerance zone. An arrow from the feature control frame must point…

A feature of size is a hole, pin, slot, width, or sphere defined with a plus/minus tolerance.

Straightness - line elements may be applied to the surface of a pin. The specification defines a tolerance zone in which the line elements on the surface must lie. The feature control frame is directed to the surface. MMC and…

Straightness of a median line defines a tolerance zone in which the derived median line must lie. When specified at MMC, it defines a virtual condition boundary which the surface must not violate. Note the feature control frame is placed…

A feature control frame creates a geometrically shaped tolerance zone within which the feature must lie. The tolerance zones may be a variety of shapes usually defined by the geometric characteristic in the first compartment and other symbology in the…

Total runout is a 3D surface to axis control. It creates one tolerance zone that all surface elements must lie within simultaneously. When applied to a cylindrical feature, the tolerance zone is the radial separation between two cylinders coaxial with…

This chart shows dimensioning symbols found on engineering and mechanical drawings. Note the comparison with the ISO standards. Most symbols have been in Y14.5 since at least 1994. Newer drafting symbols introduced in Y14.5-2009 are indicated with 09 next to them. There were no new GD&T symbols in the dimensioning section in Y14.5-2018. To learn even more, take our engineering drawing course.

There are 12 geometric characteristics with the corresponding GD&T symbols in this chart. These symbols are placed in the first compartment of a feature control frame and define the geometry characteristic of the feature that is to be controlled. The characteristics are grouped into four types of tolerance: form, orientation, location, and runout. The general primary control with a few notes is also shown. This is only a quick GD&T summary example and a more complete definition can be found later in the GeoTol Pro 2020 Fundamentals Workbook.

Note: Geometric characteristic symbols of concentricity and symmetry were removed in ASME Y14.5-2018. See unit 13 in the GeoTol Pro 2020 Fundamentals Workbook for more explanation.

Examples of all possible types of primary datum features and their corresponding datum and constrained degrees of freedom can be found here.

Collections of features may also be used to establish a single datum, but for simplicity, this degrees of freedom table illustrates only single datum features.

The DOF table illustrates primary datum features only. The degrees of freedom constrained for a lower precedence datum feature depends on its geometry and order of precedence as a secondary or tertiary datum feature.