Course Materials

Stack Up Analysis Course Objectives

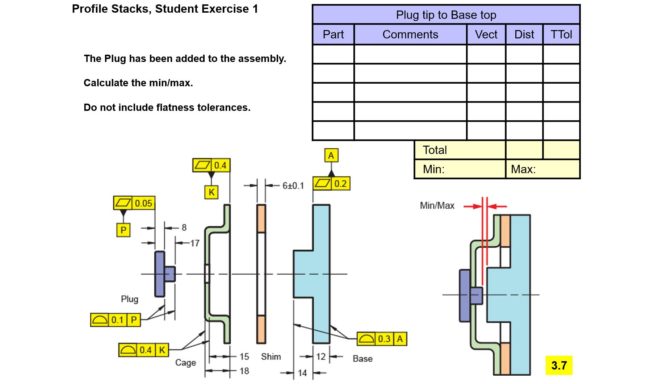

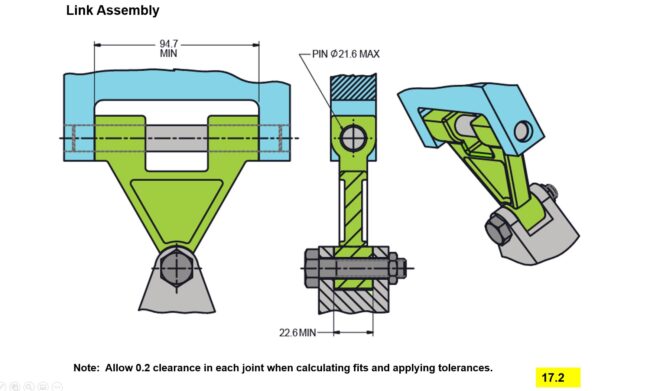

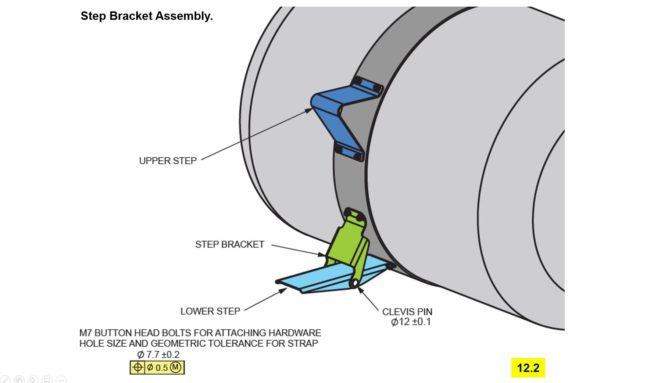

Students learn to apply geometric tolerancing on parts and assemblies in GeoTol’s Applications and Tolerance Stacks program. They will also learn to perform linear, axial, orientation tolerance stacks, and GD&T tolerance analysis to ensure functional requirements are met. After the stacks, reallocation of tolerances may be needed to meet manufacturing capabilities using worst case and RSS statistical methods.

Prerequisite: GeoTol Pro GD&T Fundamentals Course

Targeted Audience: Design engineers, drafters, manufacturing engineers, quality engineers and others involved with the creation of drawings, tolerance analysis, or design review.

Course Highlights

- Course Developed and Refined for Over 25 Years

- High-Level Design Course Using Case-Study Examples

- Learn Tolerance Stack Up Analysis and GD&T Applications in the Same Course

- Customizable Content for Focused Training

- Beyond the Theory with Relatable Examples and Practical Student Exercises

- Wood and Plastic Models Used for Demonstration

- Follows Along with GeoTol Applications and Tolerance Stacks Workbook