Expansion and Clarification of Concepts

Restrained Condition and Free State modifier

Restrained condition notes in the datum reference frame section has been expanded and clarified. Explanation of the free state modifier was also moved to this section from the form section to link the concepts. The 2018 standard gives more guidelines for the use of a restrained condition note on a non-rigid part. It lists important parameters that may be included in the note such as: magnitude, location, direction, sequence, and area of restraint. Gravity affecting a non-rigid part is addressed. Examples and rules for a restrained note and datum targets have also been added. The free state symbol may now be used on individual datum references without affecting the restraint of the rest of the part.

Axis vs Surface Interpretation for Position at MMC/LMC

In previous versions of the standard, position tolerance at MMC has been explained in terms of the feature axis within a cylindrical tolerance zone and additional (bonus) tolerance is added as the feature departs from MMC. The Y14.5 also states that position at MMC creates a virtual condition boundary that the surface may not violate. It was discovered and documented in the earlier 1994 standard that the axis interpretation and surface interpretation actual values are not equivalent because of unsymmetrical form deviations on the feature. The 1994 standard defined the surface method as the correct interpretation for position at MMC and LMC even though most of the figures showed the axis. (Note, the axis method is a more conservative interpretation and will not allow a bad part to pass.) The 2018 standard has revised a lot of figures to show the surface instead of the axis interpretation and sometimes both. Nothing has changed here in 2018 but the explanation in the figures to reduce contradictions.

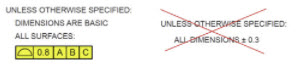

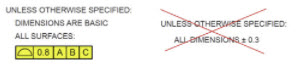

Profile in a note

The 2009 standard allowed a profile to be placed in a general note by this paragraph:

- 3.5 FEATURE CONTROL FRAME PLACEMENT

A feature control frame is related to a considered feature by one of the following methods

(e) placing in a note, chart, or the general tolerance block

The 2018 standard has clarified this in the application of the all over profile requirement:

- 11.3.1.5 Profile All Over Specification:

A profile tolerance may be applied all over the three-dimensional profile of a part UOS. It shall be applied in one of the following ways:

(c) place the profile tolerance requirement in the general tolerance block or general notes

Other examples of profile blocks in notes were also included in other sections of the document. This is another push for replacement of plus/minus in title blocks to profile of a surface relative to a datum reference frame. This has been an industry practice for years. I am glad to see it added to the standard.

Runout

Runout did get a substantial overhaul in its 2018 definitions without really changing anything. In previous versions of the standard, runout was mostly defined by the dial indicator inspection device. Throughout the past decades, the Y14.5 has been transitioning out of inspection-based definitions and into more theoretical tolerance boundaries. This allows quality to choose the best inspection method based on equipment available, expertise, capability, cost and risk. Runout was the last hold-out on the inspection-based definition and was changed in 2018.

Size tolerances are added to the figures to clarify the use of size and runout together.

Tangent plane modifier is clarified for use on runout.

Runout clarified for use on assemblies that do not rotate about the datum axis.

Continuous Feature

The continuous feature symbol is first explained in 2009 and unites two or more features of size as a single feature; the size tolerance also controls coaxiality. The 2018 standard made it optional to include nX next to the CF symbol for clarification on the number of features involved. In 2009, it was a bit unclear whether this symbol could be applied to surfaces, but in 2018, there are now two types of continuous features: continuous feature and continuous feature of size. I am still unsure of the implications applying this to surfaces and it may have opened a door into a different way of controlling relationships. Some say a flatness and continuous feature may be used to control coplanarity (usually done with profile tolerance) although there are not any examples of this in the standard. It may also replace composite tolerancing in some cases. There are a couple examples in the standard of CF being used in place of 6X or 6 surfaces, but I don’t see the benefit. I worry this symbol may cause more confusion than our classic position or profile tolerances with nX or multiple leader lines to control locational relationships between features. Be careful with this slippery symbol, especially on surfaces.