Geotol Pro Fundamentals Training Program outline

There are 10 core units, including student exercises, that the learner should focus on for the NIMS exam. These are units 1-6, 10, 11, 12, 14 in the GeoTol Pro Fundamentals Program. It is essential the first 6 core units are covered in order and reviewed in detail as they provide the necessary progressive foundation necessary in understanding geometric tolerancing.

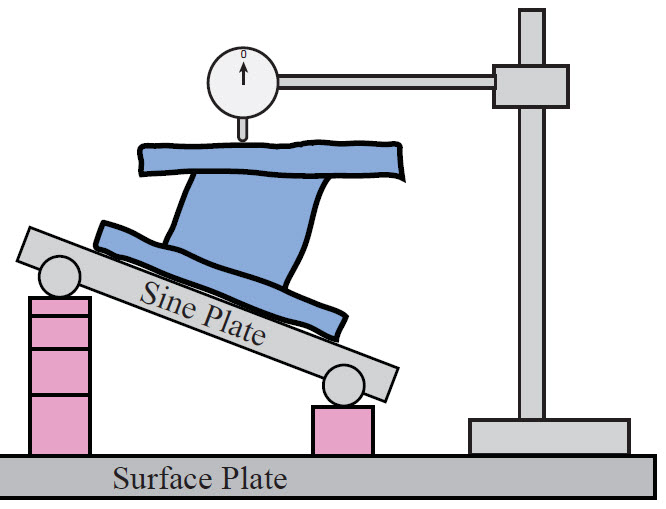

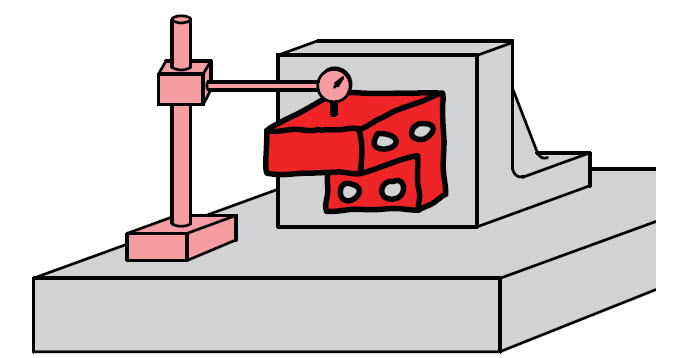

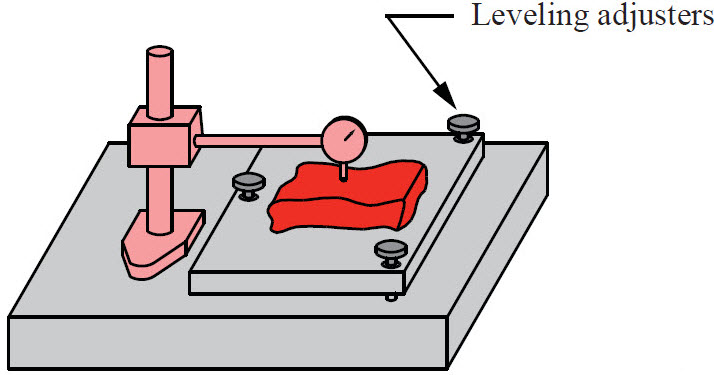

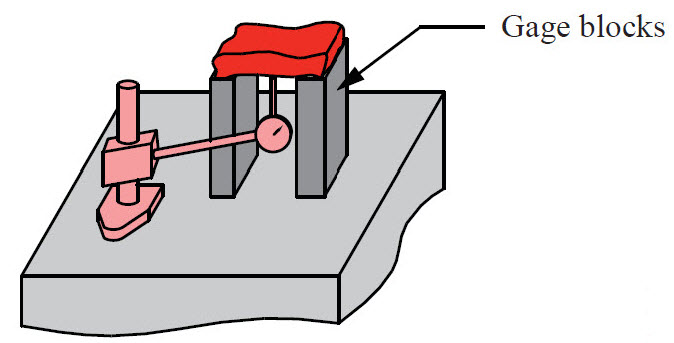

- Unit 1 (Core) includes the introduction and the symbols, terms and feature control frames used in geometric tolerancing. It also leads into a good discussion about basic inspection techniques.

- Unit 2 (Core) contains important information of the limits of size and Rule 1. The system of limits and fits in the second half can be saved for reference or later study.

- Unit 3 (Core) provides an introduction on how the Geometric Tolerancing System Works. In a practical example a datum reference frame is constructed on a plane surface part, and form and orientation tolerances are applied to qualify the datum features. Afterwards position and profile tolerances are added along with basic dimensions to complete the product definition. MMC, LMC and RFS modifiers are applied and explained. Make sure and cover this unit in great detail. In this unit there are also good comparison examples to show the differences that occur between plus/minus and geometric tolerancing.

- Unit 4 (Core) provides a series of exercises on inspection of position tolerance and the calculations necessary for data recording when feature modifiers are applied. The exercises can be completed in either inch or metric values.

- Unit 5 (Core) talks about the necessary 3 product plans and explain the process necessary as parts flow thru the manufacturing system. Virtual condition concept is explained along with exercises for the calculations.

- Unit 6 (Core) expands the 3-plane concept known as the datum reference frame (DRF). This unit explains how datum features are used to constrain the six degrees of freedom and establish the DRF. This is the most important concept in the GD&T system.

- Units 7, 8 & 9 are optional and more advanced in explaining the DRF concept in more detail. Individual units or excerpts can be included in the training or saved for later advanced study.

- Unit 10 (Core) explains how the form tolerances control the shape of individual features. Form tolerances are often used to refine the form deviations allowed by the size tolerance and rule 1.

- Unit 11 (Core) explains how the 3 orientation tolerances control the tilt relative to a datum or DRF.

- Unit 12 (Core) covers profile tolerancing and how it can be used to control the location, orientation and form when applied to a feature without size. The first part of this unit should be covered in detail with the understanding of min/max distances created by the profile boundaries and the interaction between form and orientation tolerances. The later composite profile examples in this unit cover the more advanced profile concepts and can be reviewed or left for further study.

- Unit 13 covers position tolerancing in more detail than the earlier units 3 and 4. This unit explains extended principles and allows a basic review and extended concepts of position tolerancing. The later composite position examples in this unit are optional and cover the more advanced position concepts and can be reviewed or left for further study.

- Unit 14 (Core) covers the 4 coaxial type tolerances that you would typically find on round parts. The differences and similarities are explained, and calculations are shown to compute the necessary boundaries to insure conformance.

- Units 15 is optional and can be used for design personnel and others with a mild interest in the engineering side. This unit explains how position tolerances are calculated and applied to the product for interchangeability in the design stage. There are student calculation and application exercises to in order to test comprehension.

- Unit 16 is optional and shows how to calculate boundaries for the various applied geometric tolerances. These calculations can be used by design personnel as well as manufacturing and quality to insure conformance to specifications. Calculation exercises are included to ensure comprehension.

- Unit 17 contains a series of 4 optional practical examples where geometric tolerancing can be applied based on design functional requirements. These examples can be used at any time after unit 6 to show the practical side of GD&T.