Description

GeoTol Pro Fundamentals Workbook (2009) Overview

GeoTol’s practical guide to geometric tolerancing is a professional-grade, must-have companion for any personnel using GD&T. Whether you’re learning through our GeoTol Pro 2009 Online GD&T Introduction Program, presenting the GeoTol Pro 2009 Fundamentals PowerPoint to a classroom, or watching our GeoTol Pro 2009 Fundamentals DVD series, this workbook mirrors each lesson and provides space to work through every exercise. Released in mid-2009, it remains widely recognized as the “Gold Standard” for interpreting geometric tolerancing.

Written to ASME Y14.5-2009 + ISO Alignment

This practical GD&T workbook is written to the ASME Y14.5-2009 standard and includes:

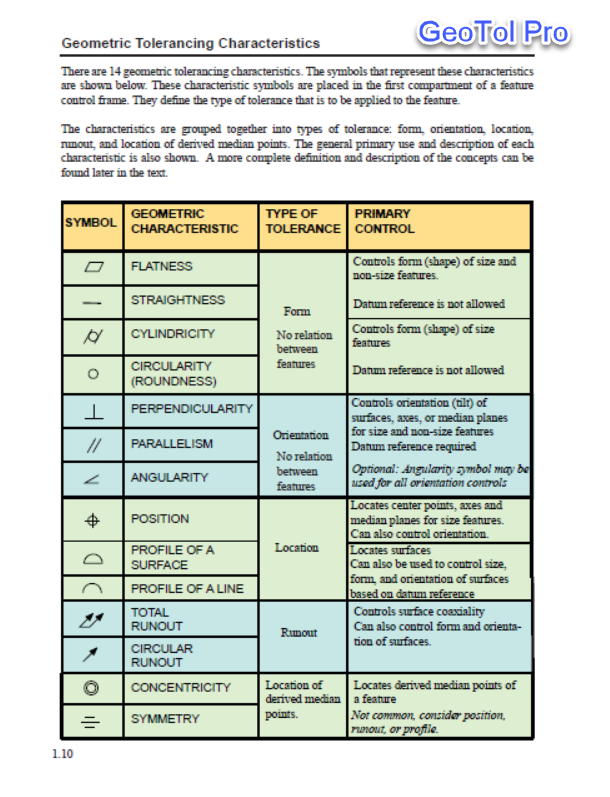

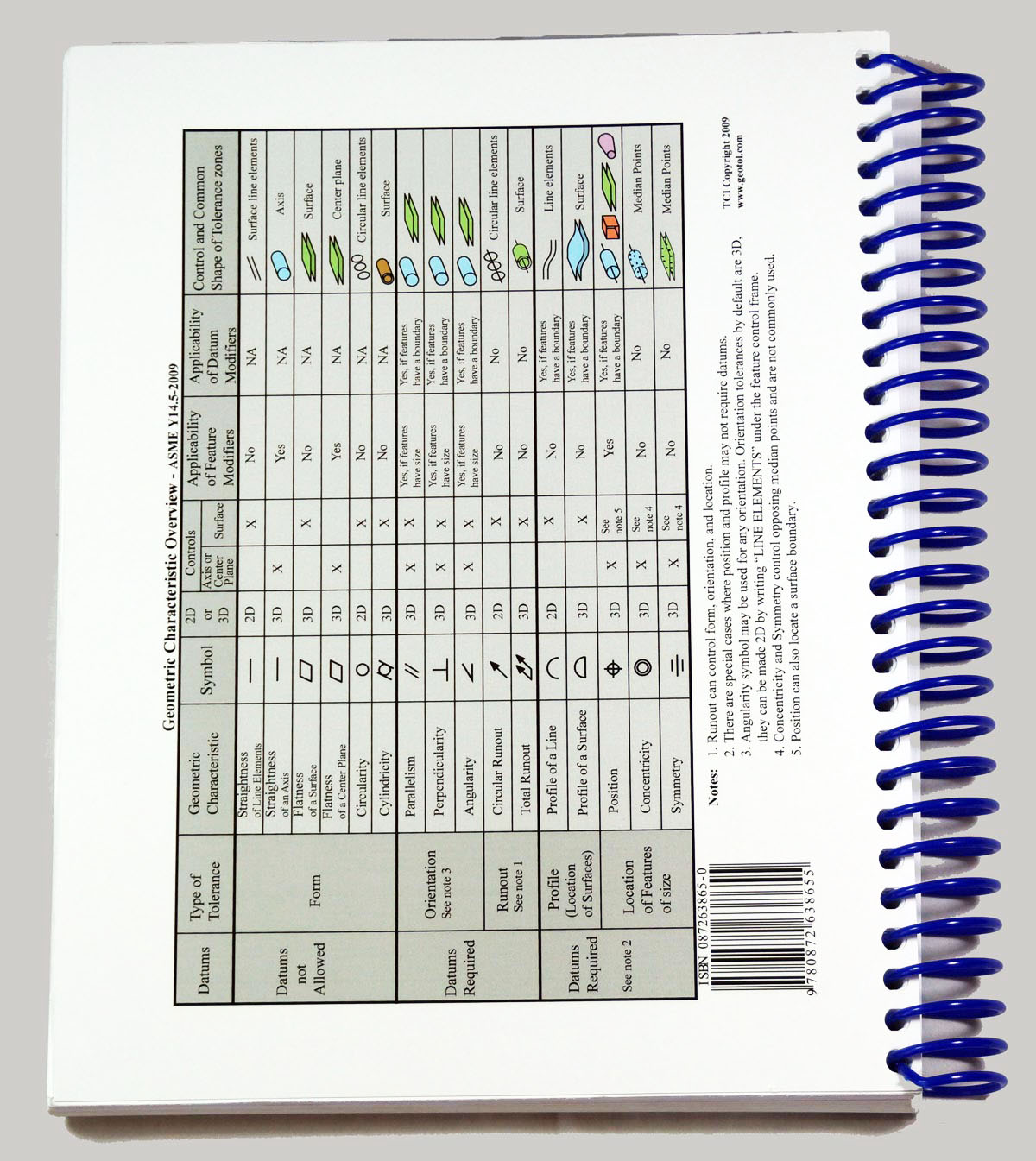

- Symbol tables for quick reference

- An appendix detailing improvements and changes from the ASME Y14.5M-1994 standard

- Excerpts noting similarities and differences with relevant ISO dimensioning and tolerancing standards

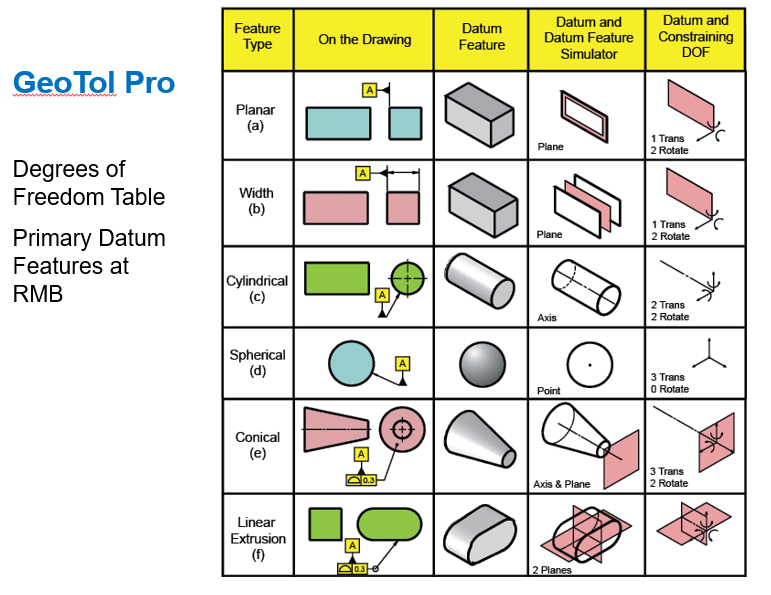

With 380 pages and hundreds of full-color graphics, the workbook brings drawings, datum reference frames, and tolerance zones to life. The high-quality visuals make concepts clear, showing how GD&T applies to modern engineering and inspection workflows.

Structured Learning From Fundamentals to Advanced Concepts

Written in simple, easy-to-understand language, the workbook features 17 units that guide learners from the basics of GD&T through advanced concepts such as:

- Tolerance boundaries

- Simple stack-up calculations

- Graphical inspection techniques

- Data reporting procedures

Hundreds of detailed illustrations show parts in real assemblies, demonstrate drawing applications, and simplify inspection methods. Exercises appear during and at the end of each chapter, allowing students to test their new skills as they progress. A full table of contents and index support quick information lookup.

Ideal for engineers, designers, manufacturing professionals, and quality personnel, the GeoTol Pro Fundamentals Workbook (2009) provides practical knowledge applicable across industries.

Instructor-Friendly Features

GeoTol Pro: A Practical Guide to Geometric Tolerancing can be used on its own or as part of a complete GD&T training system. Other resources for instructors and training leaders that GeoTol offers:

- GeoTol Pro Fundamentals 2009 Instructor PowerPoint Kit

- Over 1,700 full-color graphics

- Slide page numbers match workbook pages for easy classroom alignment

- GeoTol Pro 2009 Fundamentals DVD Series

- A 17-unit video series designed for personal, company, or classroom learning

- GeoTol Pro GD&T Plastic Model Parts Set

- 3D plastic models corresponding to workbook graphics

- Includes inspection tools such as a height gage, angle plate, sine bar, and vee blocks

- Helps students visualize and handle the parts they’re applying GD&T to

Together, these materials give instructors the ability to create an engaging, hands-on learning environment that blends visual, physical, and digital teaching tools.

About the Authors

The GeoTol Pro Fundamentals Workbook 2009 is co-authored by Scott Neumann and Al Neumann, leading experts in geometric tolerancing.

- Scott Neumann

- Mechanical engineer specializing in tolerance stack-ups and inspection techniques

- Al Neumann

- Member of the ASME Y14.5 committee for over 30 years

- Serves on the ASME Y14.5.1 committee on mathematical principles of dimensioning and tolerancing

Both authors are active contributors to ISO standards committees and have written best-selling books and video training programs on GD&T. Together, they have delivered thousands of training programs to hundreds of thousands of professionals worldwide. Their combined experience across hundreds of industries is embedded throughout the workbook, making it a trusted resource for learning and applying geometric tolerancing.